What is it for?

The shock absorber is a device used to dampen shock and vibration. It mainly controls and absorbs suspension movement on a vehicle: in this way, the suspension work or elastic movement can be modulated and adjusted, considerably improving safety and comfort during travelling.

There are several types of shock absorber. The most commonly used ones are the telescopic and hydraulic types. Other types are also available including pneumatic shock absorbers, controlled by electronic control units for comfort adjustment during driving.

How is it built?

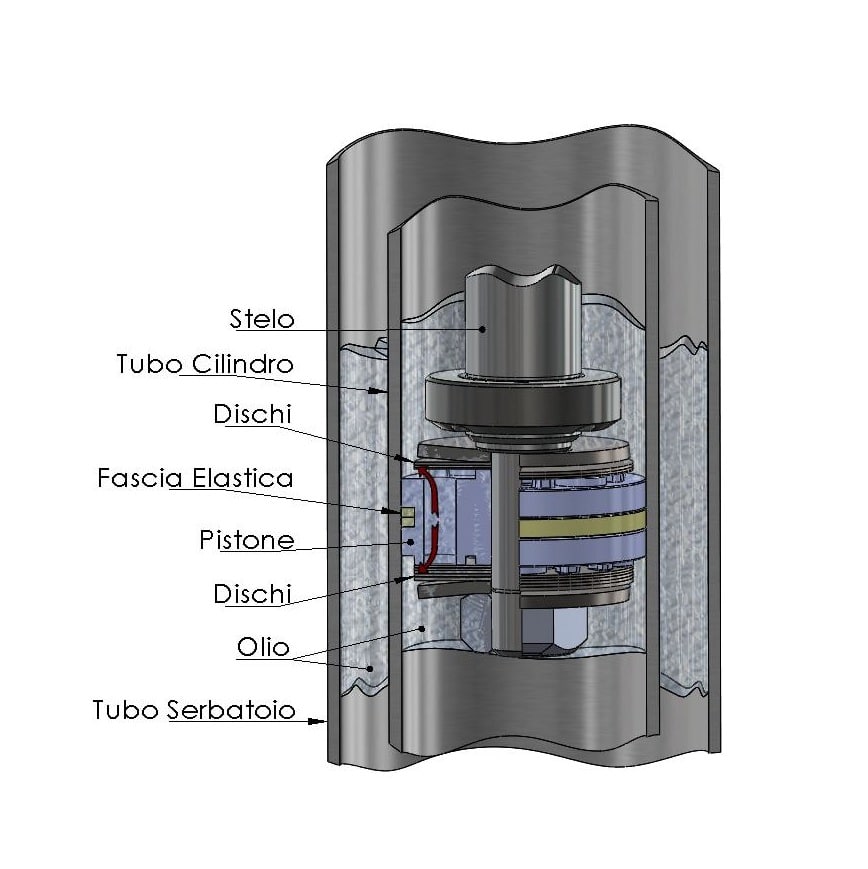

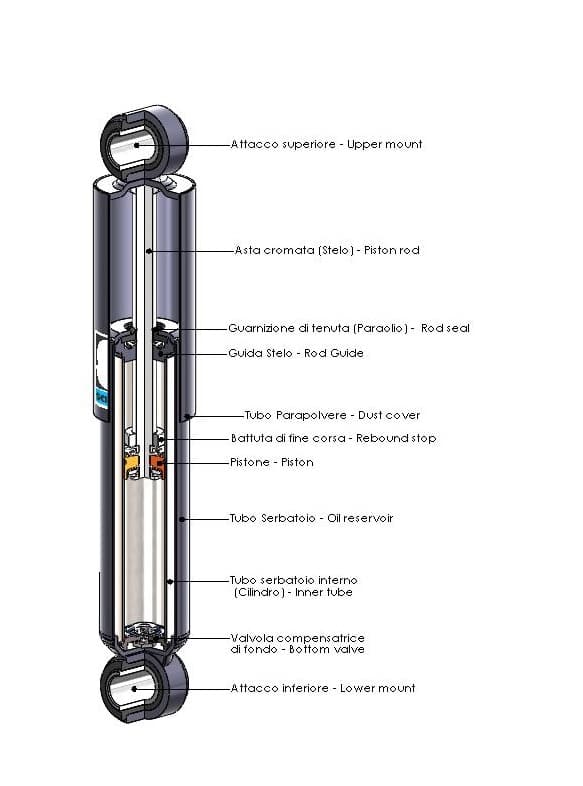

Generally, a shock absorber consists of: three coaxial tubes, a chromium-plated rod, a piston with reed valves, a bottom compensation valve, a guide for the chromium-plated rod, internal oil seals and an anchoring end.

A shock absorber is designed to absorb the suspension movement elastic force: to do this, the friction existing between the piston and the oil must be used.

On the inside, the shock absorber consists of a tube known as «cylinder» in which the chromium-plated rod runs. At the end of the rod the piston is attached, with all its compression valves, springs etc.

By sliding in the cylinder, the rod causes the oil piston to move from one end to the next, and oil to flow from one chamber to the next. Oil will flow from the inner cylinder tube into the outer tank tube.

The movement of the oil, forced to flow through calibrated ports and specially adjusted valves, will produce friction forces determining the shock absorber setting (Adjustment).